Hardware Development: from prototype to fabrication-ready

We develop smart devices, based on microcontrollers, sensors, physical parts of computers, PCBs, IoT & IIoT solutions, and make them work as interconnected systems. Additionally, we develop web and mobile applications to complete & manage the hardware part of a project.

Hardware development services are essential in several key scenarios

- When it comes to business improvement. When existing equipment fails to meet your specific requirements or is immensely expensive, custom hardware development provides tailored solutions to enhance operational efficiency and meet your unique needs.

- When it comes to launching a new business and pioneering new technologies. Starting a business based on groundbreaking technology demands custom hardware solutions: when off-the-shelf equipment is inadequate, customized hardware ensures you have the precise tools necessary for success.

- When it comes to transformational upgrades. Adapting to the demands of the modern world often requires hardware solutions that address energy efficiency, environmental impact, and other critical factors. Custom hardware development enables you to upgrade your systems to stay competitive and relevant.

Hardware Development Services from LANARS

Electronic system design

We help with the design idea — from functional block diagrams and power estimates to selecting the basic components. Alongside process design and planning, our experts handle the hardware requirements specifications.

Electronic design

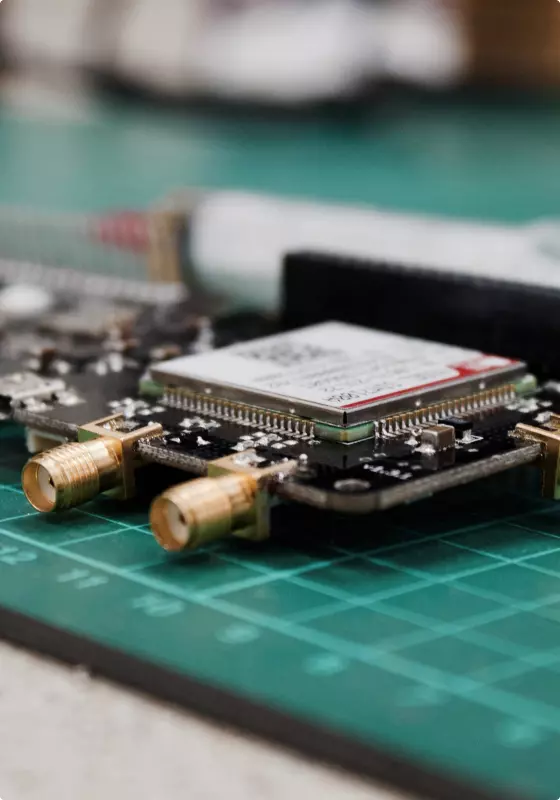

LANARS hardware team works on creating schematic designs and BOM cost estimation. We provide custom hardware services for System-on-Chip (SoC), System-on-Module (SoM), and Single-Board-Computer (SBC) development.

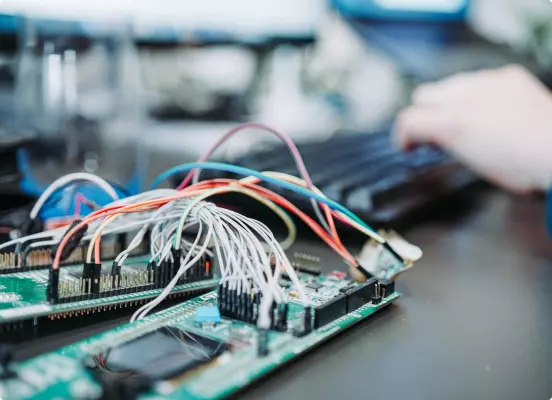

Prototyping and assembly

Fast prototyping — realization of your ideas within the shortest period of time, ensuring Proof of Concept, and then getting down to prototyping. Component-level repairs and other microoperations require micro soldering — another service provided by our hardware experts.

Preparing for manufacturing

During preparation for manufacturing, our hardware development department analyzes the created design, compiles reports, and may create a flat version of the model. The main goal here is to eliminate possible errors and inconsistencies before the manufacturing process starts.

PCB Layout

Another block of the hardware development services includes stack-up or build-up development. Our team handles transmission line configuration and arrangement.

LANARS' unique hardware lab enables us to create multi-layer, flex, and rigid-flex PCB design, high-speed PCB layout, and radio-frequency (RF) PCB designs. High-density interconnects (HDI), the fastest growing technology, is also our expertise area.

Basic and full component placement needs high accuracy and great attention, as it is one of the most important processes in PCB development — our expertise in the field and successful products on the market prove our reliability.

Design for manufacturing (DFM), design for assembly (DFA) — no matter what the complexity of the idea, we carry out the project on a turnkey basis. End-of-Life and cost-reduction redesigns are also a part of our expertise.

Testing, validation, and certification

LANARS hardware team carries out all types of testing. These include hardware initial tests, functional tests (basic testing of working capacity), and advanced tests (full testing of all the board elements, sensors, indicators).

The validation phase is required to make sure that the device complies with the technical task and specific requirements from our client. Then comes certification, which means that our specialists take the manufactured product to specialized centers to get valid certificates (CE, FCC, etc.) — this enables the product to be marketed in the target country.

Hardware Product Development Life Cycle

Hardware development process at LANARS consists of several stages.

Based on an individual or company need, a statement of need or concept proposal is formed, reviewed by the senior management and sent to the product development team. There may be a need for a new or custom product, or re-engineering of an existing one.

This stage begins immediately after concept proposal approval. The scope of the concept is defined, cost benefit analysis is conducted and a feasibility study is carried out. Project management and risk management plans are established. The team defines the need of the end user, whether it is feasible and ways the product can be realized.

During this stage inputs, processes, outputs and interfaces should be defined — in other words, we define what functions should be performed by the product.

Taking all the requirements into consideration and focusing on how the required functionalities can be delivered to the product, the design process starts. Preliminary design is the first element which establishes top level architecture and functional blocks with their inputs and outputs.

Here, the developed design turns into a physical product. All the agreed specifications are translated into software and hardware. The stage includes processes such as: embedded hardware development, embedded firmware development and product enclosure development. Testing consists of independent testing of software and hardware, and then testing of the whole system for functionality.

During deployment the first fully functional model of the product is launched onto the market or handed over to the client. Integration tests may be performed and the developed product becomes operational.

Maintenance of the product in its environment is performed during this stage. Malfunctions and errors can be observed in order to fix the bugs.

Upgrades are the development of newer versions of the previously designed product. Major bug fixes or a need to add a new feature may trigger the upgrading process.

The current product may be announced as outdated, if the manufacturer sees an opportunity to embark upon a more powerful technology on the market. The crazy pace of technological evolution may invoke the announcement of new versions, or even the retirement of an existing product.

How we make it possible

The combination of a modern laboratory with cutting-edge equipment and a team of experts makes LANARS one of the most outstanding hardware developers in Europe. Our hardware team includes experienced professionals who have a background in hardware development for the space and aircraft industries — that is why we’ve hired our staff from the heart of the space engineering industry, Ukraine.

We create power and high-frequency electronics, do embedded programming (Assembler, VHDL, VERILOG, C, C++, Python) and use numerous modern tools for hardware.

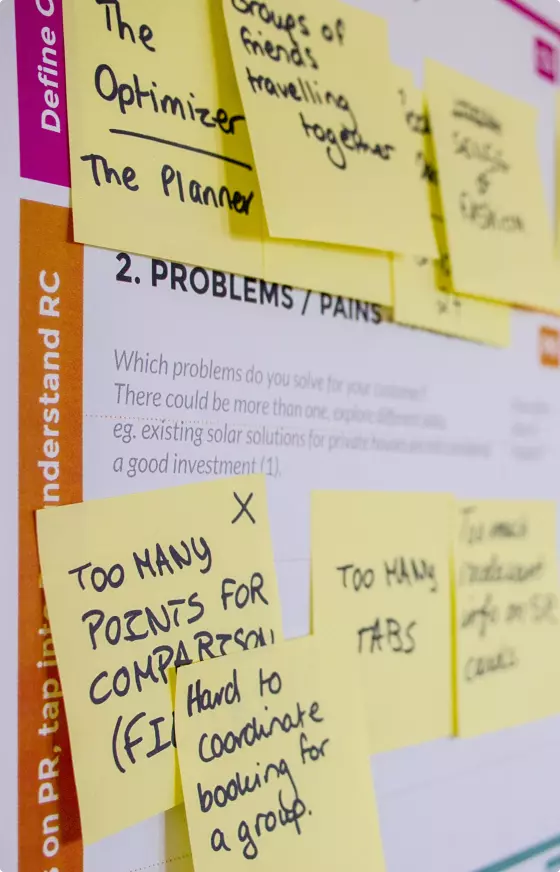

Business Analysis is important

Maximum immersion into the project and a precise understanding of the client's needs are necessary for comfortable stress-free cooperation. That is why we have devoted a huge amount of effort to develop our expertise in business analysis. The business discovery stage helps understand the end users, their needs, and requirements. Because of that, our clients get:

- cost savings;

- uncertainty reduction;

- increased implementation speed;

- reliable timing and quality.

Selected cases

Get started with Lanars

Tell us about your project. We respond to every inquiry within one business day. Really!